Do you plan to install radiant floor heating in your home? Do you not know if the coating of your house is apt to install a radiant floor? We tell you which is the most viable floor to install underfloor heating in your home.

Taking into account that the radiant floor is a highly efficient heating system, it is important to know the type of floor that a house must have to install it. Although it is a system compatible with most soils, we want to tell you what is best for you because of its high thermal capacity. Take note!

What types of floors are suitable for radiant floor heating?

It is important to know that before installing a floor heating, consider the type of floor on which it will be installed. In this sense, we highlight several types:

Laminated floor

The laminated floor consists of a set of sheets or layers made of different materials. These sheets are usually melamine that has been previously pressed and have a wood-like finish. Its durability and resistance to humidity make it an excellent choice for radiant heating.

It is a floating platform that acts as the base of the radiant floor. The main advantage of this type of floor is that it saves the economic cost of installing a radiant floor considerably. It must be kept in mind that no glue is necessary for the installation of the platform so that at the moment of the installation of the radiant floor a slightly hollow sound can be felt with each step.

Parquet floor

The ideal parquet for underfloor heating is the solid parquet. It is a parquet that has several varnished layers, an inner layer of different materials and another layer of solid wood. Although its price may vary depending on the materials of the layers, it is considered a fairly economical material.

Its main drawback is that it can not be easily sanded. Also, the ability to adapt the parquet floor with the radiant floor will be based on the thermal resistance of the floor and the dimensional stability.

Wooden floor

The wood becomes another material suitable for underfloor heating, as long as it is quality wood. The main factor in these cases is the density of the wood because depending on it, the transmission of heat will be higher or lower.

In this case, it is important to eliminate all types of humidity. So that, the transmission of heat to the home is complete, and any type of deformation of the material can be avoided.

It becomes an excellent material for the floor of the house due to its great thermal capacity. Now that you know which is the most suitable floor to install radiant heating, do not wait any longer to request the help of a professional to install your radiant floor.

How does a floor heating system work?

On numerous occasions, we have heard the following: “in hot winter feet and the cold head.” Well, simply with this phrase, it can be understood that underfloor heating is a sign of comfort since the temperature of the air at the height of the feet is slightly higher than the air temperature at the height of the head.

The explanation of how it works is very simple. It consists of a network of cross-linked polyethylene or polybutylene pipes, which are installed under the pavement and a layer of self-leveling mortar, through which hot water circulates at a temperature between 30ºC and 45ºC.

It is the heating system that uses the lowest water flow temperature. As a reference, a conventional radiator installation uses a water temperature of about 70 ° C.

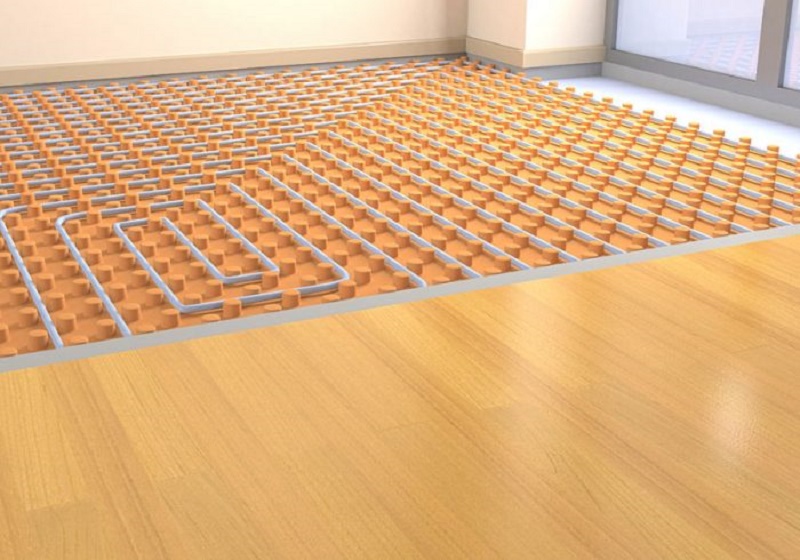

How is a radiant floor system installed?

The installation of a floor heating system is very simple because

- Prefabricated elements are used

- On the prefabricated elements, the pipes are arranged

- The pipes are installed in the form of a coil, double coil or spiral

- Through the pipes, we circulate hot water from a heat generation system.

Absorb the dilatations produced by the cement mortar placed on the emitter tubes, due to its heating/cooling. Likewise, it generates lateral isolation of the system. It is fixed to the walls of all areas to be heated, from the base floor to the upper level of the pavement baseboard/perimeter installation underfloor heating. Energy efficiency. radiant floor installation

Radiant floor polyethylene film:

It is an anti-humidity barrier between the base floor and the radiant floor emitting surface placed on top of it, in such a way that it avoids the rise by moisture capillarity.

It is usually installed when there is a risk of moisture in the floor/slab. It can come incorporated in the insulating panel.

Radiant floor insulation panel:

The thermal insulation of the system. It is essential for any radiant floor heating installation. For this purpose, insulating panels are used on which the pipes are installed. These panels can be molded, holding the circuits and facilitating their laying with the projected pipe spacing.

Radiant floor pipes:

To carry out the laying of circuits from the collectors, pipes of plastic material with oxygen diffusion barrier are used. They are usually polyethylene or polybutylene pipes, special for this heating system.

Cement mortar underfloor heating:

Once the circuits are installed, pour the cement mortar over the entire heating surface. The recommended thickness is 5 cm measured from the upper generatrix of the pipe. It is very important to add an additive to the mixing water of the mortar mixture, to achieve a correct contact with the emitting pipes, avoiding inclusions of air, which would increase the thermal resistance of the system.